We take it for granted that we can turn on the tap, take a shower or flush the toilet at any time of the day. With our pressure boosting systems – that we tailor to the application- we ensure a problem-free user-experience to the comfortable and consistent water pressure delivered with minimal energy costs. Keeping water supply in homes, offices and industrial applications self-evident.

Applications

Appartment buildings | offices | skyscrapers | hotels | ships | football stadions | hospitals | food factories | process industry | Reverse Osmosis | laboratories| Utility projects

Proven reliability

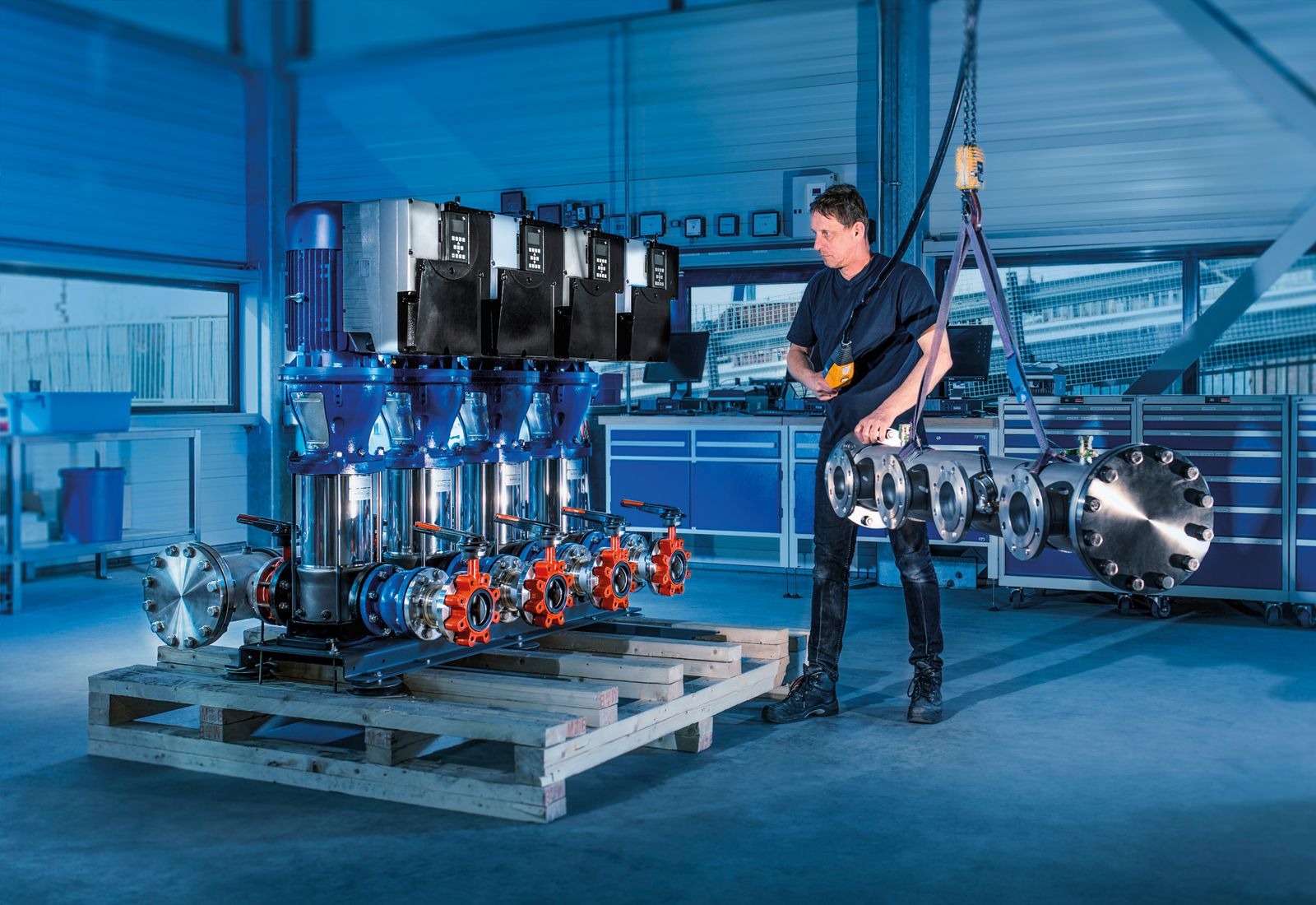

A DP-Pumps booster system is real Dutch crafmanship. Every detail of our booster systems, from the hydraulic parts to the pipework and the control unit, has been developed and made in our 16.000 m² factory on the basis of many years of experience.

Direct contact with the factory has many advantages:

- A lean process makes it possible to produce simple and advanced installations in a day.

- The support team can respond quickly if you have any changes in delivery times or specifications

- You can consult with Product Engineers and arrange trainings with Product Specialists

Service-friendly design

Continuity of water pressure is one of the most important elements in the technical design of our installations. Every booster system that we supply is assembled, programmed and tested in our factory for quick installation and comissioning on site.

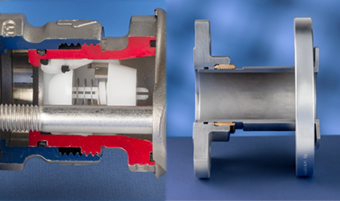

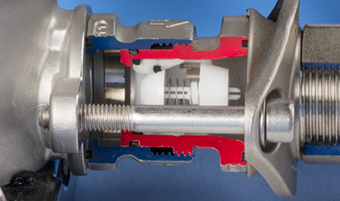

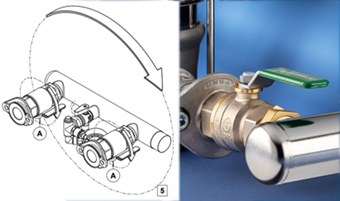

- The smart design of the manifolds makes it possible to “mirror” the manifold on site, allowing connection of the installation to the main water supply on either the right or left side of the booster.

- “Flex flanges” in combination with adjustable non-return valves and adjustable “Easy-fit” fittings, make it easy to align the manifolds and set the correct tension during installation and maintenance.

- You can even service the pump and non-return valves without interrupting the building’s water supply.

- With the intelligence of the DP-Control it is easy to adjust the settings to your needs.

Flow-through design

Care for water quality

Every detail of our booster systems, from the design, choice of materials and the organisation of our production processes, contributes to guaranteeing the highest level of water quality.

- all components, from pressure vessel to the chamber behind the ball valves give 100% flow-through. This prevents potential (Legionella) bacteria from multiplying in the biofilm of standing water.

- In our production facility we operate strict safety requirements, and the safety of the test water is guaranteed by purification, constant change and regular sampling.

- All materials used meet or exceed the strict standards imposed by European legislators.

Efficient and durable

Our pumps use energy efficient electric motors (IE3 and IE5) as standard and we produce installations with advanced speed control to further increase efficiency. In each configuration, enlarged flow diameters of the pipes and settings ensure minimal pressure loss. Together with custom configuration and accurate calculation from our experts we create the most energy-efficient pump installation for your building.

How do you select the right booster system

Customised systems – competitive prices

When you need advice or support, you can trust that we are always there for you. For example, when choosing the right system for your application. An over-dimensioned system wastes energy, that is not a sustainable situation and will cost more money than is necessary. If the system is too small it will result in complaints about a lack of water pressure. Determining the right size of the system starts with an accurate calculation.

Our technical advisors convert the details from a building into designing a customized booster. By correctly calculating the system based on the periods of average water demand, energy savings are made, peak time water pressure delivered and optimal efficiency achieved.

Customers around the world

Whether you order a standard 3-pump installation for a large, new build residential project; a 1-pump installation on a freighter; or a large 6-pump installation with advanced control for a luxury hotel, all our systems are made by skilled technicians, dedicated to deliver the right system for your application.

Broad range

9-960m3/h pump solutions for pressure boosting up to 25 Bar

The extensive range of pressure boosting systems offers solutions on any scale. There are systems that will increase the pressure in a single home all the way to full systems for the tallest skyscrapers.

We produce many thousands of booster systems every year for customers around the world.

Hydro-Unit Premium Line

The standard for the safe transportation of drinking water

- Stainless steel AISI 304 of 316

- Advanced control unit DP-Control

- Fixed speed or variable speed

- 2-4 pumps

- Capacity up to 88 m3/h

Hydro Unit Utility Line

Versatile powerhouse for demanding applications

- Stainless steel AISI 304 of 316

- Advanced control unit Megacontrol or tailored control panel

- Fixed speed or variable speed

- 2-6 pumps

- Capacity up to 960 m3/h

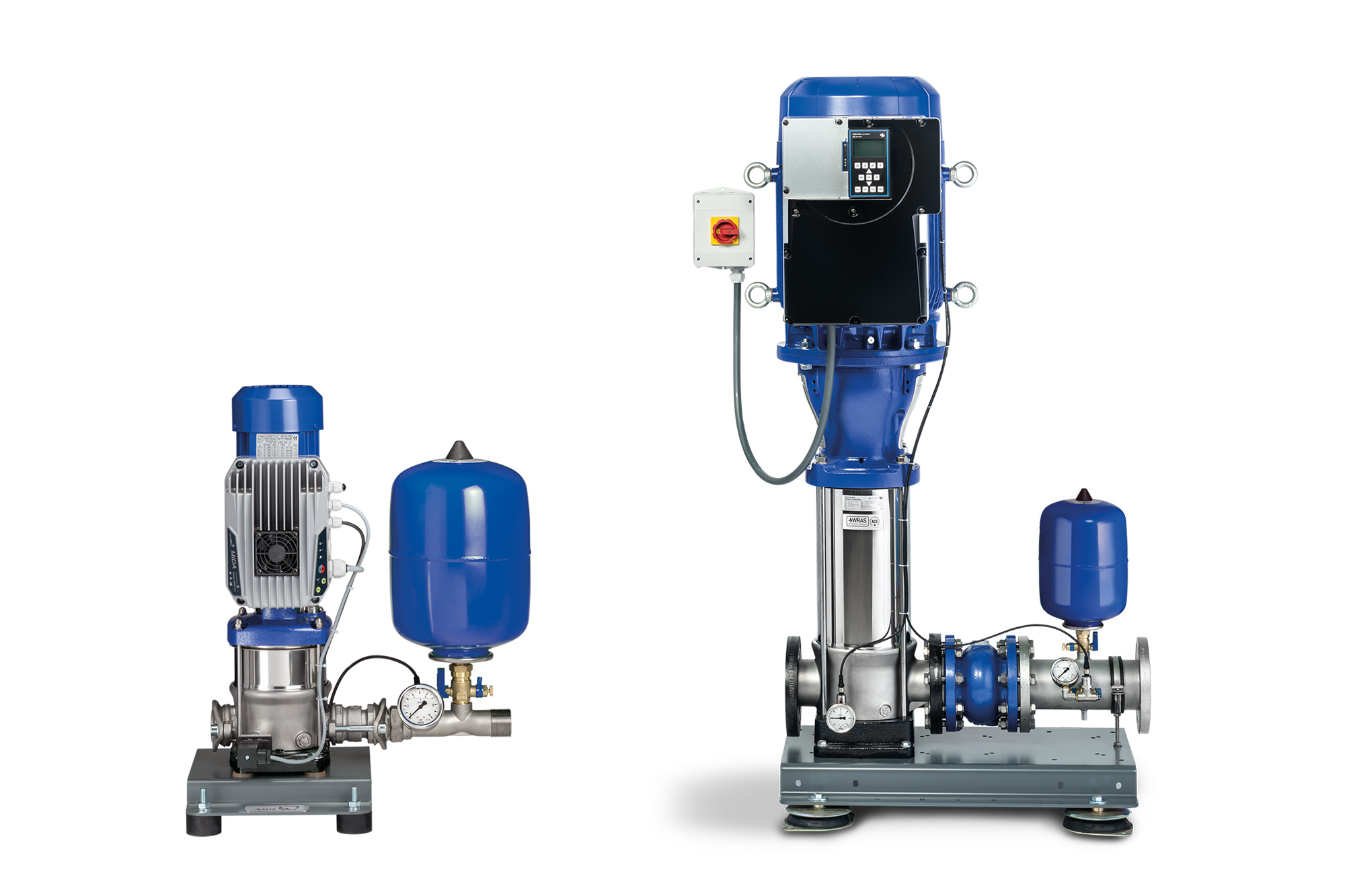

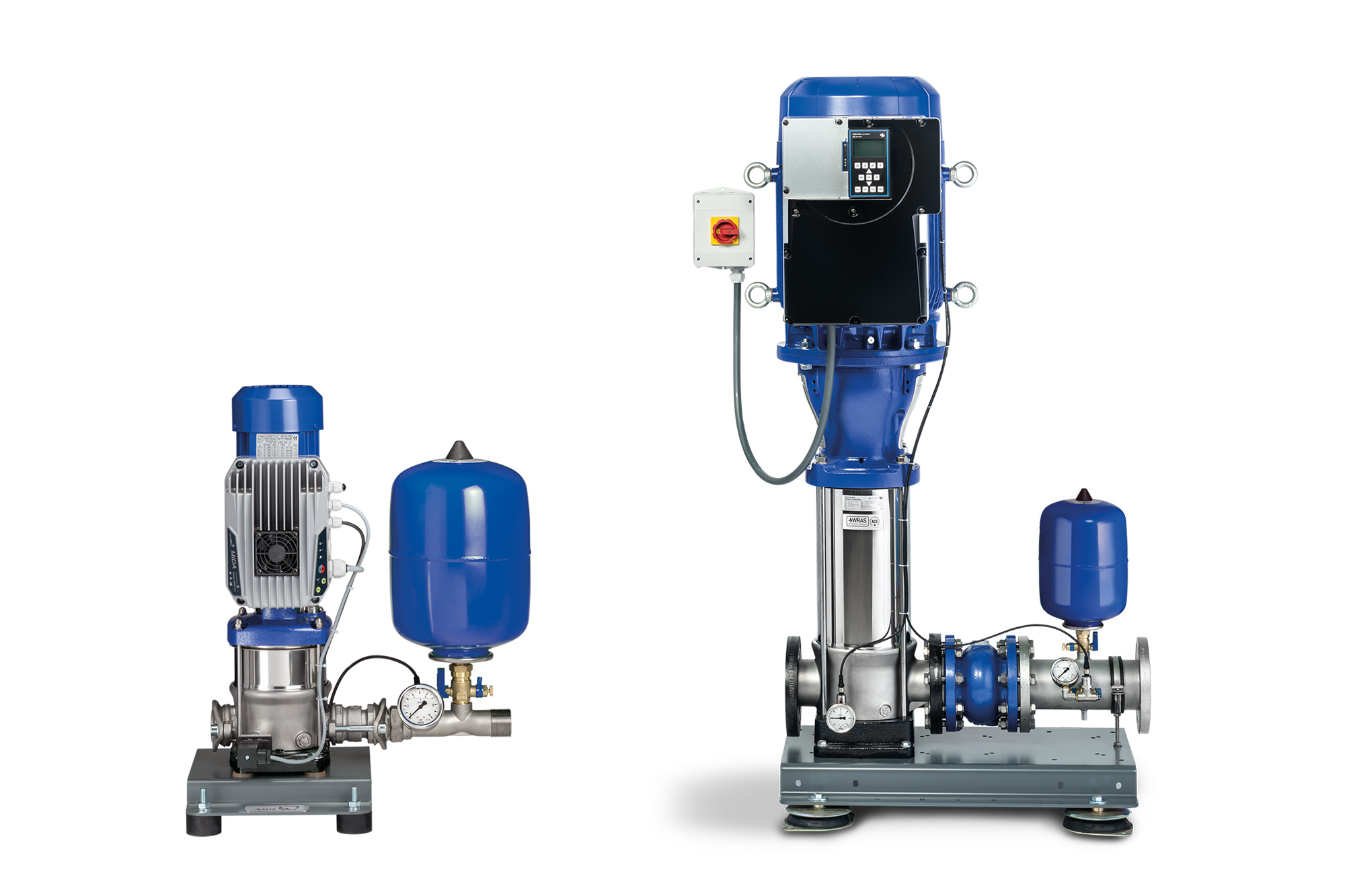

Hydro-Unit Single Line

Professional 1-pump booster system with drinking water certificate

- Stainless steel AISI 304 of 316

- Standard control unit

- Fixed speed or variable speed

- Capacity up to 76 m3/h

Hydro-Unit Base Line

Basic booster system with frequency inverters on the pumps

- Stainless steel AISI 304 or 316

- Standard control unit (on the pumps)

- Fixed speed or variable speed

- 2-4 pumps

- Capacity up to 88 m3

Hydro-Unit Single Line | Base Line Economy

Compact and economical

- Stainless steel AISI 304 or 316 / high quality cast iron

- Standard control unit

- 1 or 2 pumps

- Capacity up to 18 m3

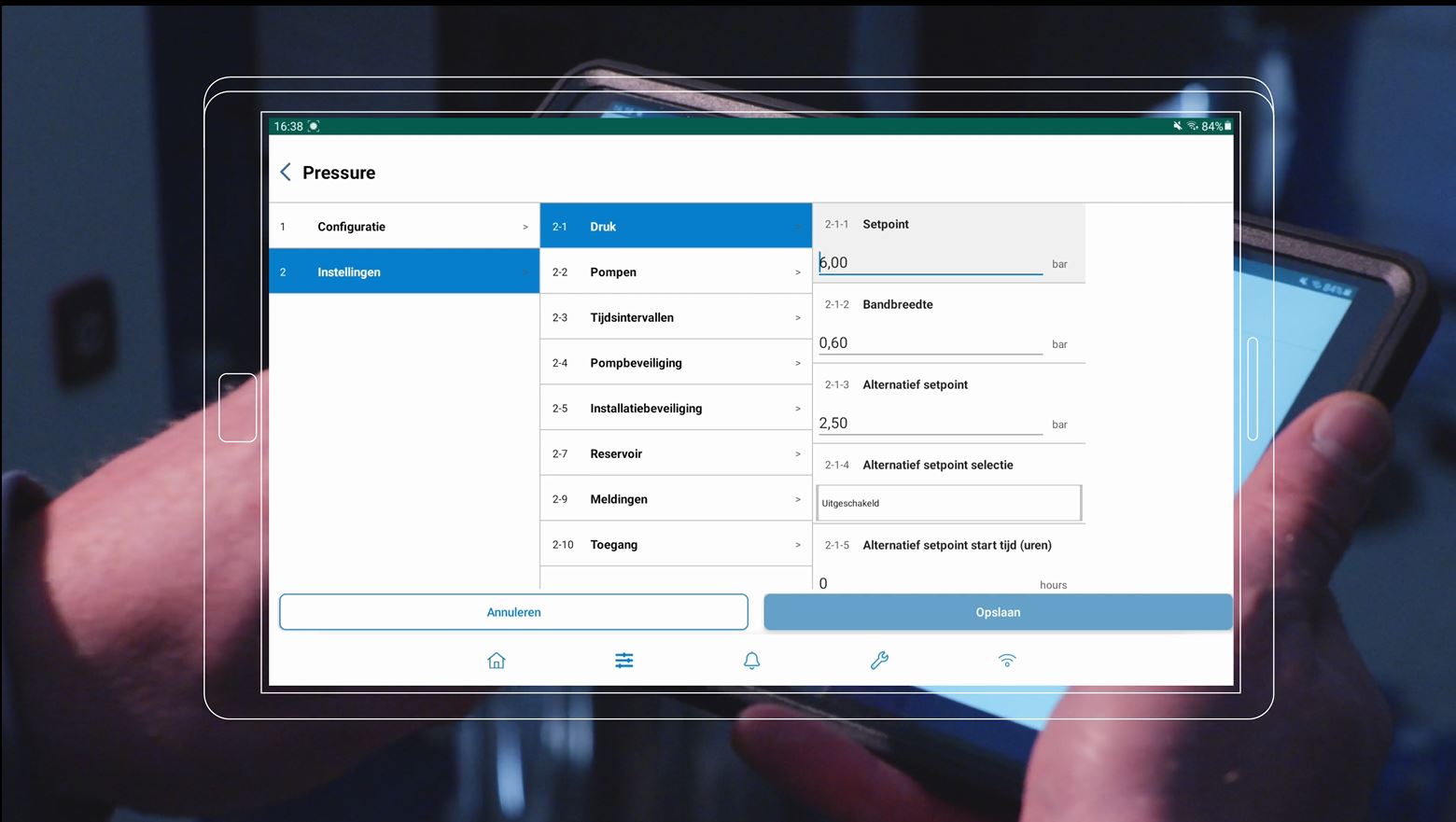

User-friendly control unit

Adjusting an installation to the application? This is easy with the DP-Control control. The pre-programmed functions make the control usable for:

- Fixed speed or speed-controlled

- Jockey pump control

- Base-Peak load control

- Level control in a reservoir

- Redundant system

Via the display and the extensive App you have all important information at your fingertips, settings can be easily adjusted and management information can be read out.

Frequently asked questions