The best pump for your installation or process is one that fits the application and connection exactly. That works for years without problems and of which, if necessary, the spare parts or replacement are always quickly available. That is why we deliver every pump tailored to the application, from a Dutch factory with professional support.

Applications

marine | sport stadiums | hospitals | pressure boosting systems | food, chemical and process industry | hot water and boiler feed | domestic water supply | reverse osmosis | fire fighting | irrigation | cooling water transport

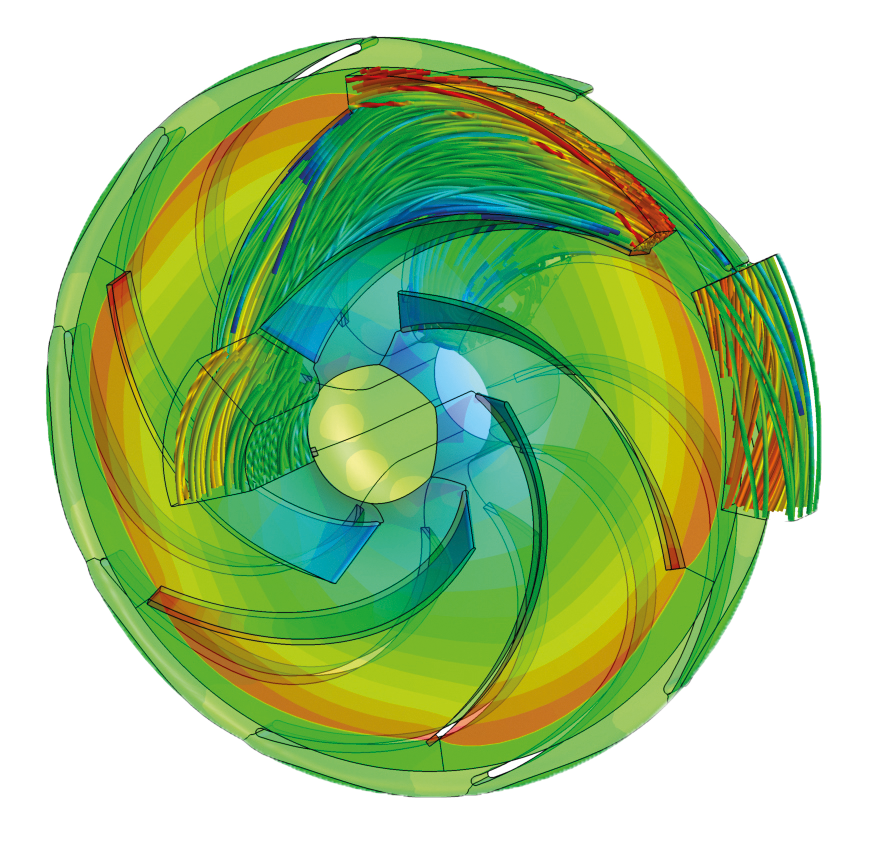

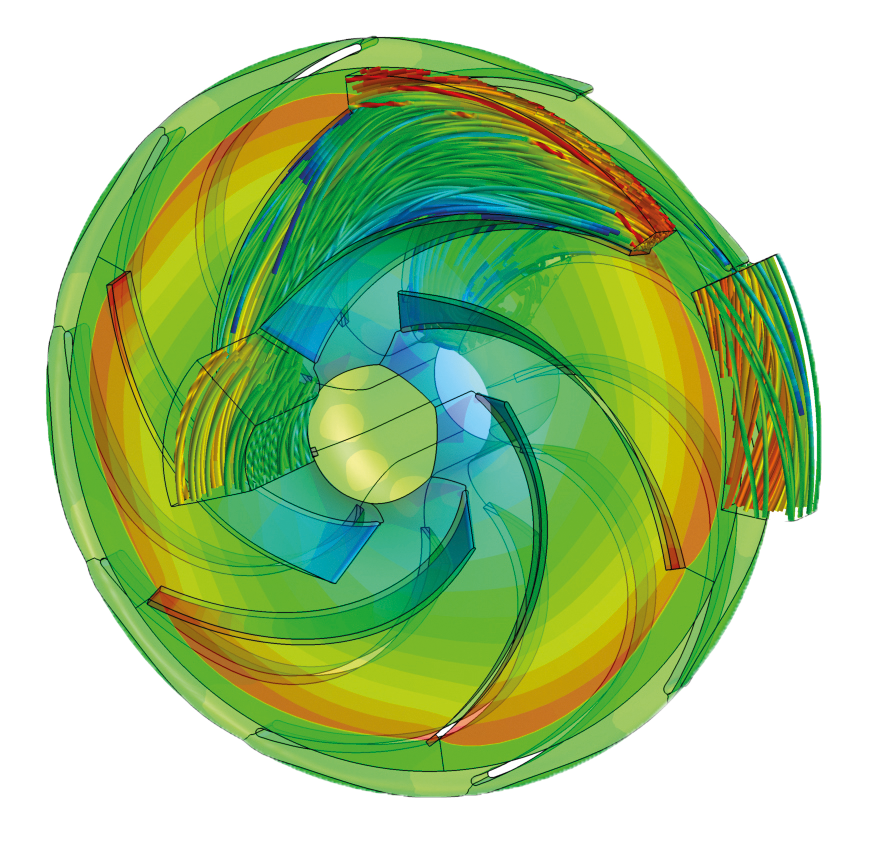

Advanced hydraulic design with Dutch roots

We like to keep control over quality and always remain flexible

A DP-Pumps stainless steel pump is real Dutch crafmanship. Every detail of our pumps, impeller, stage casing, pump shroud and control unit, has been developed and made in our 16.000 m² factory on the basis of many years of experience.

Direct contact with the factory has many advantages:

- A lean process makes it possible to produce simple and advanced pumps in a day

- Custom parts, colours or configurations can be ordered for a single order or integrated in our standard configurations

- The support team can respond quickly if you have any changes in delivery times or specifications

- You can consult with Product Engineers and arrange trainings with Product Specialists

Custom pumps with the delivery time of a stock item

A special seal or a tight delivery time? That probably sounds familiar to you. That is why all our processes are set-up for a fast, 100% correct production of tailor made products.

A sophisticated process enables us to easily build any of the more than three million variants of our pump configurations. This way you will always receive a pump that fits exactly in your machine or process with the delivery time of a stock item.

Suitable for demanding applications

Stainless steel is a great material. It is durable, wear-resistant, corrosion-resistant and very well-suited to preserve the quality of drinking water. What’s more, it can be moulded into the perfect hydraulic shape. This reliable base is suitable for R.O. installations and boiler feed, but also as a process water installation in a food factory or car wash.

“The quality of a drinking water pump combined with the durability of a process water pump.”

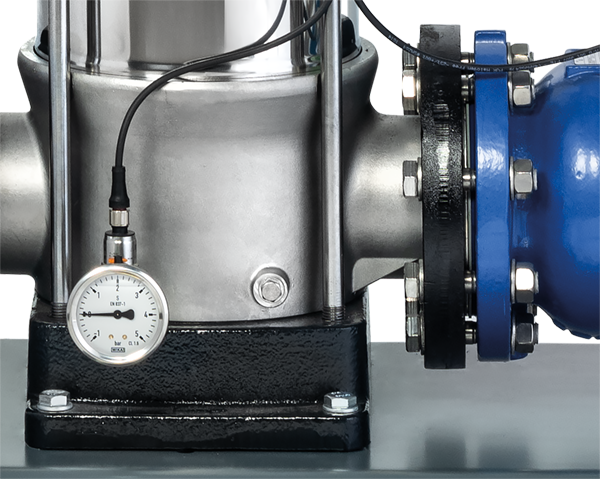

This is why we make our pumps service-friendly

Just like any manufacturer, we don’t like it if we have to interrupt the processes in our factory for maintenance or downtime. You want to solve problems quickly and replace parts in no time. That’s why our pumps are designed with a few useful features:

- Extra stainless steel plugs for filling, venting and connecting measuring equipment

- Pumps are easily interchangeable one-for-one between DP pumps and other manufacturers

- Easily accessible for servicing, often without the need to disassemble the pump or motor, or any special tools

- Use of standard shaft seals (EN12756)

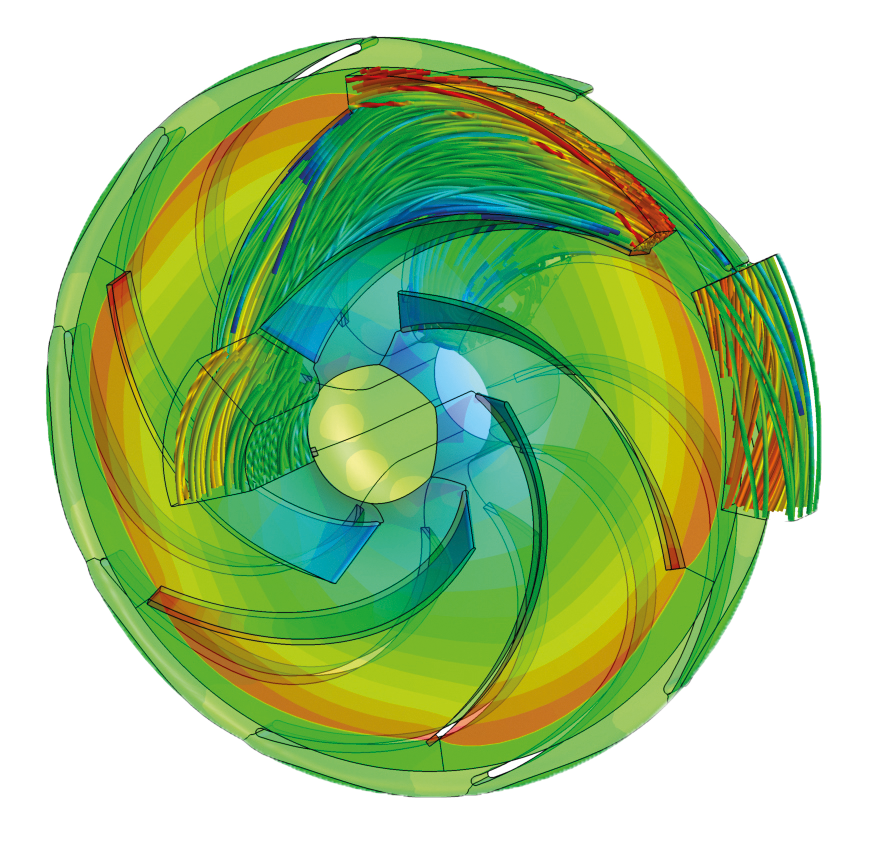

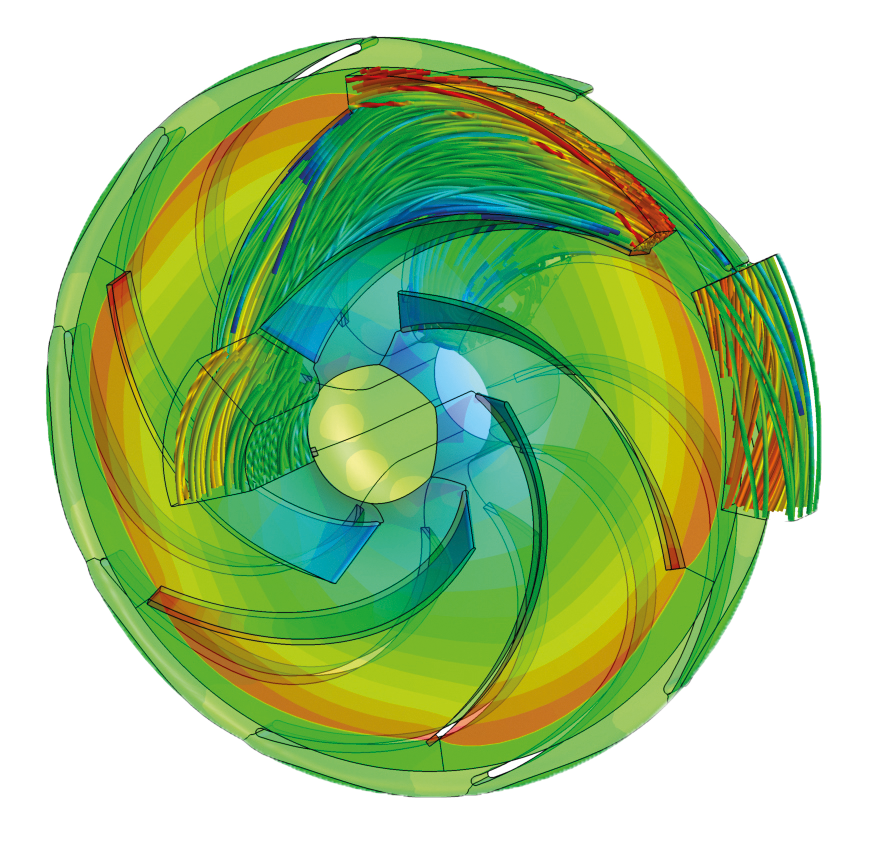

“DPV Pumps have the highest hydraulic efficiency in it’s class.”

Energy efficient and durable

In each pump the fluid flow is efficient and optimized due to a specially designed stage casing and pump casing.

- High energy savings and extended life cycle

- Significant lower NSPH values (0,6 mwk up to 5,0 mwk at Qopt)

- Specially designed low NPSHr impeller and bottom stage casing

Advanced control

The more powerful the motor, and the more operating hours it racks up, the larger the impact on its net efficiency. The intelligent DP-Pump controls offer the optimal combination of the hydraulic performance and motors we use.

In Europe, motors must meet the IE3 standard, but IE5 is now becoming the preferred choice. Within this standard the operation of the motor, together with an intelligent control system, is adapted by us to external circumstances.

Thanks to the effective communication of the controls, our products ensure optimum energy management in every situation, and they continue to guarantee the continuity and quality of your processes.

Support you deserve

Do you work with pumps on a daily basis? Then you probably know exactly what you need. But if you don’t, or if you are facing a special challenge, you can trust that we are always go the extra mile to support you with:

- the selection of the right pump

- remote assistance or on site visits

- engineering a tailored pump that fits your application

Our experts are fully trained in pump technology and will come up with exactly the right recommendations.

DPV

Vertical multi-stage centrifugal pump

- For drinking water transport and heavy duty process water applications

- Over three million different configurations

- Highest hydraulic efficiency

- High quality stainless steel; AISI 304 of 316

- Capacity up to 125 m3/h

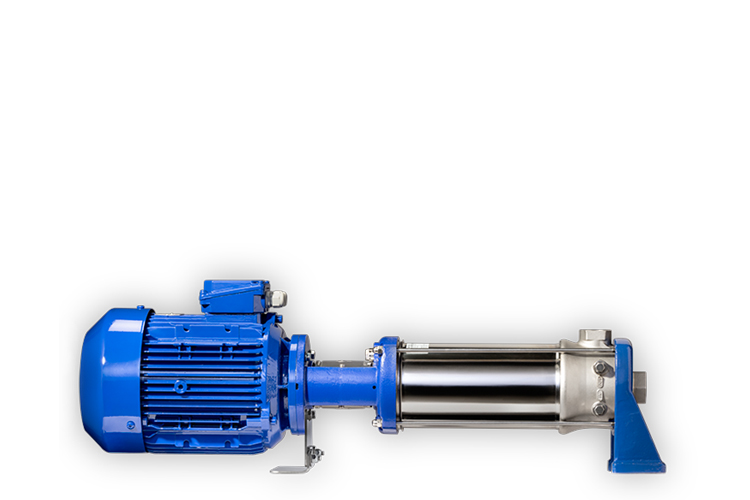

DPH(S)I

Professional horizontal multi-stage centrifugal pump

- Designed as a genuine ‘industrial’ horizontal pump

- High levels of efficiency

- Suitable for drinking and industrial water: AISI 304 of 316

- Low NPSH option

- Capacity up to 26,3 m3/h

DPHM

Compact, horizontal multi-stage centrifugal pump

- For light industrial applications, irrigation and drinking water transport

- Economical solution, great performance

- Suitable for a wide range of fluids (AISI304)

- Capacity up to 26,3 m3/h

DPVCI

Stainless steel multi-stage centrifugal submersible pump

- Developed to lift process water, coolant and lubricants from a reservoir (AISI304)

- High levels of efficiency

- Vertical mounting

- Stainless steel AISI 304

- Capacity up to 27 m3/h

- Head Hmax 256 mwc

Frequently asked questions